3 Ways Advanced Planning and Scheduling Helps Industrial Manufacturers Boost Efficiency

3 Ways Advanced Planning and Scheduling Helps Industrial Manufacturers Boost Efficiency

3 Ways Advanced Planning and Scheduling Helps Industrial Manufacturers Boost Efficiency

Apr 6, 2023

Aptean Staff Writer

Aptean Staff Writer

Are you building the right jobs at the right time? Are you fed up with doing all your scheduling processes manually? Do you wish you had more time on the shop floor to finish more tasks? With staggering lead times, lack of advanced planning and the unpredictable nature of supply chains leading to fluctuating inventory levels—maximizing production and resource efficiency is critical to your industrial manufacturing operation.

Despite technological advancements, many manufacturers continue to rely on manual workflows for planning and scheduling tasks, making it harder to resolve issues.

While sometimes necessary, handwritten notes require time to decipher, and paper schedules cannot easily accommodate last-minute changes. The greatest risk associated with these manual processes is the potential for inaccuracies, which can negatively impact the entire business. Also, relying on manual data tracking methods for scheduling and planning can result in decreased productivity and costly overtime. That is why manufacturing scheduling software is often sought after by industrial manufacturers to automate and streamline their planning and scheduling processes.

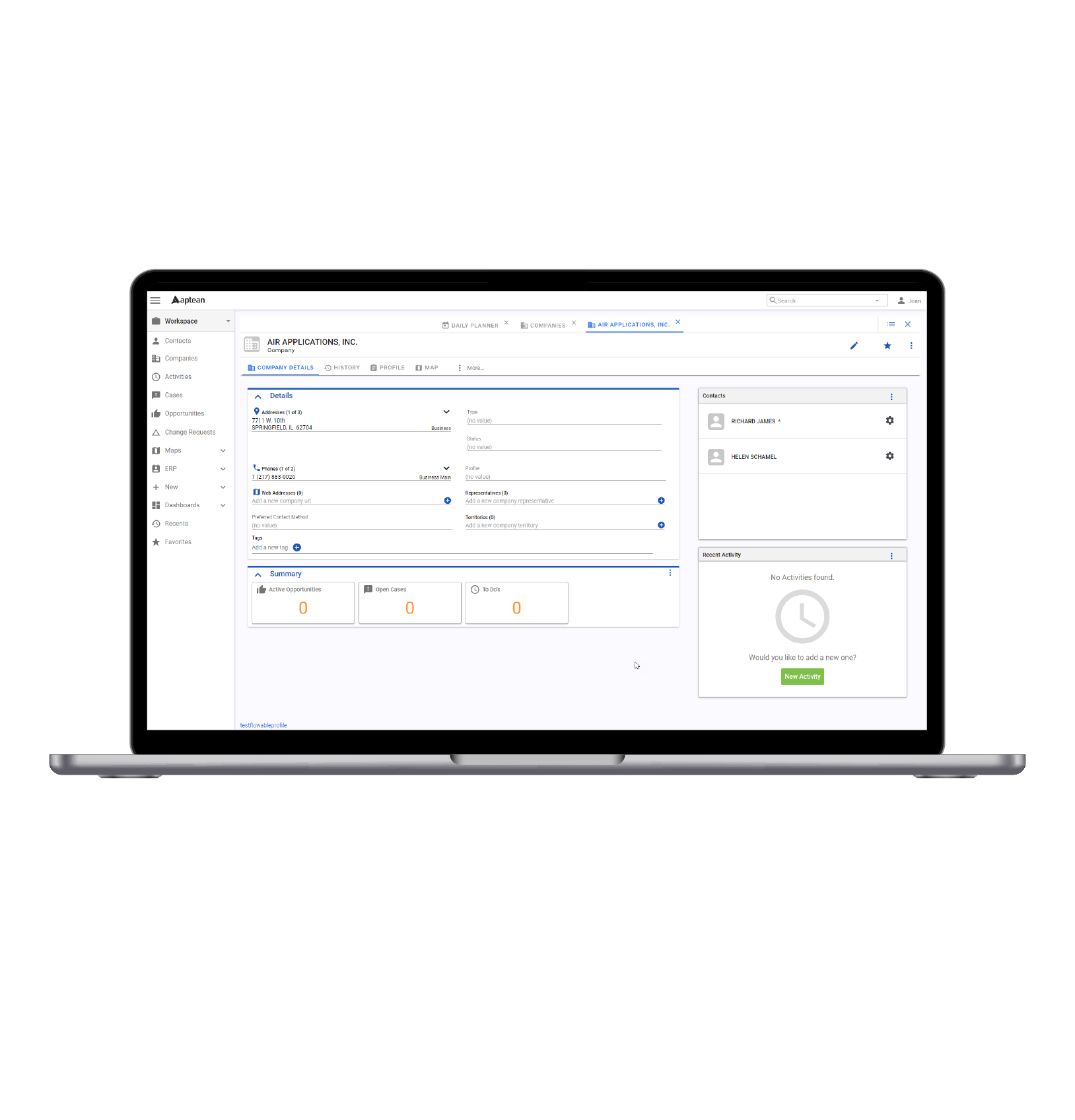

Aptean’s 2023 Manufacturing Report highlights that 89% of organizations say technology is their gateway to an improved and faster workflow. Just like them, you can boost the efficiency of your manufacturing processes with the help of advanced planning and scheduling (APS) within an industry-specific enterprise resource planning (ERP) system.

If you still rely on these manual operations, you might not have the competitive edge to go toe-to-toe with other industrial manufacturing organizations. To kickstart your initiative to give your business an efficiency boost, we will examine three ways an industry-specific ERP with built-in APS capabilities can help.

1. Improve Visibility with Production Management

Your ERP solution should give you more than just a bird’s eye view of your production processes. It should provide detailed insight into how your resources are being utilized and help you identify any potential bottlenecks where improvements are needed the most.

The performance information captured by an ERP is a powerful tool for making decisions for allocating your resources to achieve the maximum impact. For instance, it is common for manufacturing businesses to have downtime on their equipment. Knowing this vital information in real-time will help you immediately shift production to another machine or assign more staff to solve the problem.

With visibility supported throughout the organization, your workers will have easy access to job orders, peg individual job tasks to related sales orders—like quoting and estimating—and ensure that large-scale orders or projects meet specific delivery dates.

of organizations say technology is their gateway to an improved and faster workflow

2. Streamline Production Process, Equipment and Resource Management

Consider this scenario: You have an essential and high-priority order that requires the operation of a specialized packaging machine; however, it will require dedicated usage only within a specific timeframe. Without proper production process management, shop floor employees will have a hard time identifying whether the packaging machine is available for use when they need it.

With in-built APS functionality, industrial manufacturers can save valuable time and resources with the proper aligning of processes, equipment and other production resources. Manufacturing production scheduling software accounts for available resources, order priorities and lead times when optimizing production runs. With all the available information, the module can create a detailed schedule that helps streamline plans and expedite the whole production process.

Benefit from reduced lead times, improved order fulfillment processes and increased shop floor productivity when utilizing advanced planning and scheduling integrated with Aptean Industrial Manufacturing ERP.

3. Optimize Capacity Planning to Meet Shifting Customer Demands

Customer demands fluctuate regularly; that’s why analysis of current trends is essential to stay ahead of the competition. However, analysis alone isn’t enough to see a change in your business’s overall performance—you need to optimize capacity planning to meet these shifting customer demands while also ensuring that production costs are controlled and customers are satisfied.

With the aforementioned unmatched data visibility of ERP software, you can level up your manufacturing operations with improved efficiency and reliability. Then, with a solution that allows you to forecast and prepare for challenges before they happen, you will be ready to adjust business decisions for increased profitability.

An industrial manufacturing ERP solution with advanced planning and scheduling functionality can help by providing accurate data and insights for managing production schedules based on stock levels, availability of resources and lead time for components.

One ERP Solution to Supercharge Your Business’s Efficiency

Without knowing the automation tools and advanced methods available to become efficient in planning and scheduling, you could be limiting your organization’s potential for success. Implementing an ERP solution with a built-in APS module is a great starting point to drive efficiency across your shop floor operations.

Aside from production schedule optimization, reducing inventory costs and minimizing lead times, our superior manufacturing scheduling software uses state-of-the-art scheduling algorithms with real-time capabilities—and results. Your business can immediately gain enhanced visibility into production, streamlined production processes and accurate capacity planning with Aptean Industrial Manufacturing ERP as the foundation of your digital transformation.

An added benefit of choosing Aptean for your ERP needs is our flexible cloud deployments on the Software as a Service (SaaS) model. Gain greater scalability, enhanced data protection and wider accessibility with cybersecurity from cloud-enabled ERP software, all while avoiding the need to purchase additional hardware to run the system on-premise.

Are you ready to drive greater efficiency across your operations? Aptean Industrial Manufacturing ERP can give your business a solid boost to achieve more progress. Contact us today or request a personalized demo.

Request a Callback From a Manufacturing ERP Expert

Discover the benefits of software designed specifically for the discrete manufacturing industry.