Agility is a Key Characteristic of Successful Distribution Businesses

Agility is a Key Characteristic of Successful Distribution Businesses

Agility is a Key Characteristic of Successful Distribution Businesses

Jan 6, 2021

Jim Endres | Regional Account Director

Jim Endres | Regional Account Director

The annoying thing about markets is that they have this habit of always changing.

Managing this constant change can be hard, particularly for distributors of food and other consumer products that have large delivery fleets and must constantly adjust fleet sizes, routes and timetables to remain efficient. An agile business model is essential for successful distribution businesses.

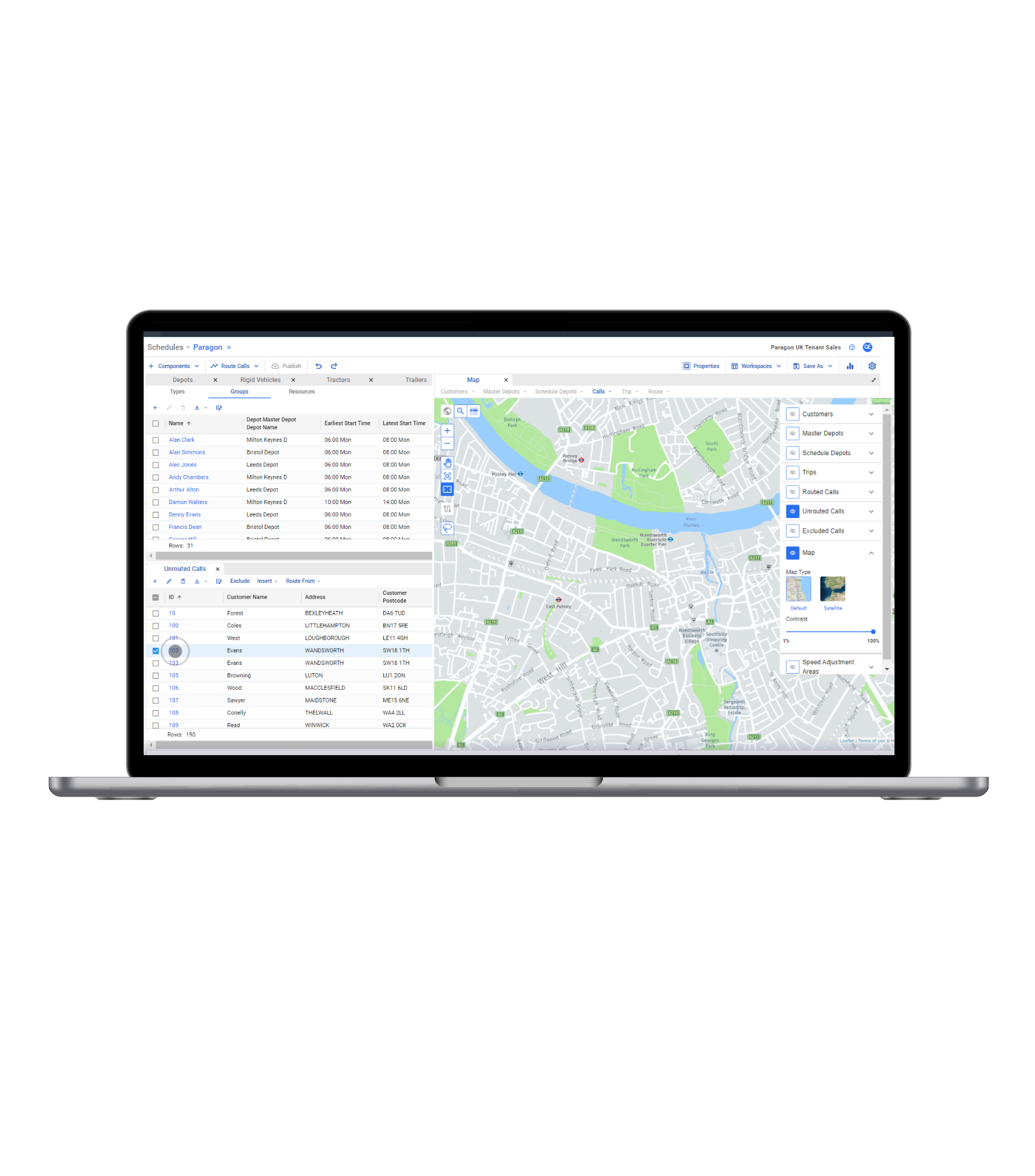

A big part of becoming agile is the software used to plan delivery routes and schedule drivers and vehicles. The wrong choice can severely hinder your ability to compete.

Consider this analogy. A small family of three saves up to buy a new car — an affordable sedan. Six weeks later they learn that the mom is pregnant — with triplets. They eventually have to sell the brand-new car at a 20% loss and must invest even more to buy an SUV or mini-van that can handle a family of six. The original car choice they viewed as affordable and practical was simply not future-proof and actually cost them far more in the long run.

There is no shortage of choices with truck routing software — from the most basic to the most advanced. A basic, easy-to-implement solution could be the best choice for a small fleet operator with less than 10 vehicles, all dispatched from the same location. If the business grows and customers become more demanding, the functional limitations of basic packages can leave you at a competitive disadvantage — something we refer to as the cost of easy.

Agile distribution businesses have common characteristics. Let’s look at five key ones and how a distributor’s choice of routing software can impact business performance.

1. Agile Distributors Embrace Growth

A basic routing solution for one central distribution center (DC) won’t work as you expand geographically and need multiple DCs. Basic packages require a plan for each location, but true route optimization uses one centralized plan to direct customer orders to the DC that can provide the fastest, most economical delivery for that order.

Sure, you can make a sub-optimal approach work. But over time you’ll drive many more miles than needed and excess miles will require more fuel, increased maintenance and the costly addition of trucks and drivers. None of these are consistent with a successful distribution business.

2. Adapt to Ever-Increasing Customer Expectations

Amazon has conditioned people to expect fast, free delivery in their personal lives. That attitude is now evident in the product distribution space, where customers want increasingly tighter delivery windows.

Adapting to these new expectations requires advanced truck routing software that places greater emphasis on plan accuracy. Such software considers dozens of variables to predict more accurate delivery times — things like average road speeds based on time of day, known construction-zone delays, and unloading times at specific customer locations along a delivery route.

These sophisticated algorithms allow you to get pretty aggressive with ETA predictions. One food service company uses advanced routing software to successfully meet a standard delivery window of 15 minutes. Solutions that utilize more simplistic algorithms simply can’t achieve anywhere near this degree of ETA precision and customer confidence suffers.

3. Improve Continuously

Agile organizations view improvement as a process, not an event. That process requires the right technology with delivery truck routing.

The heart of route optimization is the ability to compare the route plan with actual route performance in real time. You can have the best route plan possible, but if it doesn’t get followed — if dispatchers reassign drivers or drivers change the sequence of deliveries — then the benefits of that plan are lost.

You need route planning software that integrates with your in-cab telematics system and downloads data in sub-minute intervals to address this problem. This data helps you compare planned versus actual performance on delivery route progress, travel times between customer sites, stop times and other factors that could impact ETA. Variances are flagged and customers can be alerted, avoiding unhappy surprises. Most importantly, actual performance data gets fed into the truck routing software, making future plans more and more precise.

When choosing a routing system, look for one that is already integrated with your existing telematics system. Aptean Routing & Scheduling Paragon Edition, for instance, integrates with more than 40 different vehicle tracking systems, including Geotab.

4. Proactively Manage Change

Agile, successful distribution businesses don’t get caught by surprise. Surprises can happen easily if you’re managing a busy delivery operation that’s constantly changing. Profit-draining inefficiencies creep into your route plans largely unnoticed.

Sales may say yes to a request from a large customer for a tighter delivery window or, for a new customer, sales may agree to twice-a-week drops to a remote location. When this happens, you lose some of the routing efficiencies of the existing plan and your cost to serve skyrockets.

Advanced truck routing software enables you to proactively model the impact of proposed changes on both service levels and cost before they are enacted. These modeling tools provide the objective evidence you need to negotiate an adjusted rate with the customer based on the added costs you will incur.

5. Plan for the Future

A successful distribution business adapts well to change, but at the same time has a clear vision for the company’s future and the different paths to get there. The same modeling tool that can monitor your cost to serve can allow you to map out strategic changes in your fleet operations to better support growth. We’re talking about a highly sophisticated if/then calculator that allows you to play out the implications of various distribution strategies:

What if we added a new distribution center?

What if we moved our DC to a more central location?

What if we changed our fleet makeup to include a higher percentage of smaller, more economical vehicles?

The software takes your existing data on volumes and locations, then changes certain parameters to give you a very precise read on how costs and service levels would change given the alternate strategy. Once the data is loaded, the analysis itself takes just minutes to execute.

You can choose software that lacks this distribution network modeling functionality — and perhaps pay a little less in the process — but in doing so you become less agile and miss strategies with the potential to deliver six- and seven-figure cost savings.

Successful Distributors Leverage Technology to Continually Optimize Fleet Performance

KPMG reported that 92% of CEOs feel organizational agility is critical to business success, but just 27% regard their own companies as highly agile in its recent study, Achieving Greater Agility. Distribution businesses must close this agility gap to be successful. One smart place to start is technology that automates and optimizes one of your biggest cost centers — your delivery fleet. You need a comprehensive solution that is truly future-proof.

Contact our route optimization experts to discuss how the right truck routing software can help you adapt fleet operations to constantly changing market conditions.

Tried the Product Tour and Ready to Get Into Gear?

Book your full demo with our team today to see how our advanced routing software can help you accelerate performance.