Aptean EAM, API PRO Edition - Integration

Aptean EAM, API PRO Edition - Integration

Aptean EAM, API PRO Edition - Integration

Apr 29, 2019

Aptean Staff Writer

Aptean Staff Writer Headline

- An Integrated Solution for a Maintenance Management System Requires Simplicity and Openness Towards Other Information Systems Within the Company

Aptean EAM API PRO Edition is optimized for easy system integration due to its open structure and specific modules for export and import of data. Aptean EAM has successfully been integrated to condition monitoring systems, document management systems, control systems, ERP systems, HR systems and many other external systems.

Today, most Aptean EAM interfaces are based on the use of web services, which are increasingly setting the industry standard of how openly systems should be able to communicate with each other. Furthermore, the database structure and the special transaction handling with full debit/credit control have been developed specially for a controlled data exchange between external systems.

ERP Integration

Maintenance systems handle functions of essential importance to enterprises. This is why many ERP systems today also offer a maintenance management functionality. The benefits of using a maintenance management system heavily depend on whether it is successfully adopted by technical personnel. ERP systems tend to be designed using financial systems as templates. In comparison, the Aptean EAM system is designed by engineers specifically aiming to serve the needs of your technical staff.

Interfaces for Leading ERP Systems

To create the most efficient system integration at your plant, we have designed Aptean EAM to share business processes with ERP systems. The interface reference list covers most well-known ERP systems.

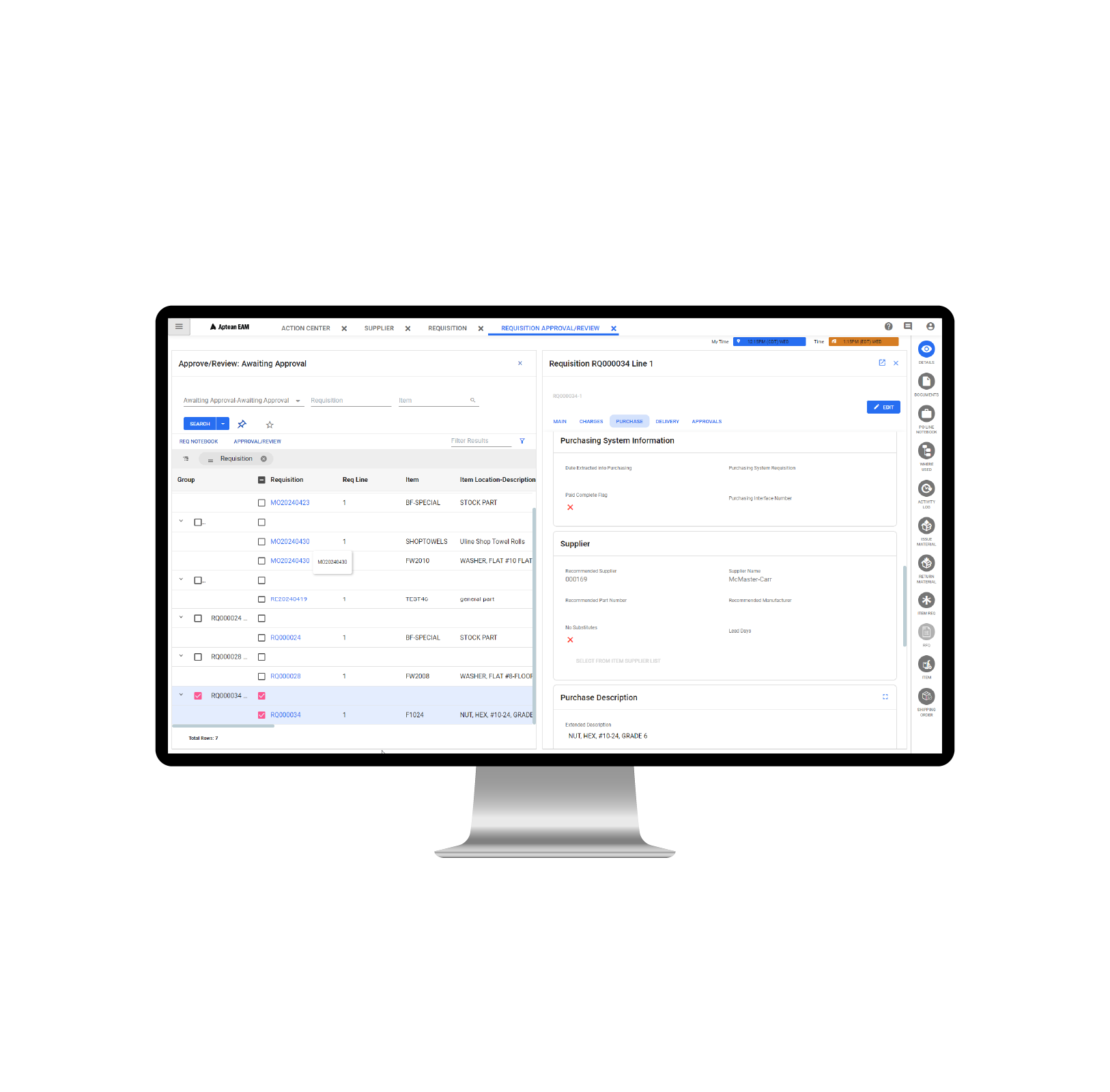

We leave it to our customers to decide which business processes of their maintenance management should be handled by Aptean EAM and which should be handled their ERP system. The business processes to consider here are primarily: stock control, purchase management and handling of invoices. Our toolbox contains the components necessary to build interfaces for sharing business processes between the maintenance system and the ERP.

In some cases, customers have decided to use the purchasing functionality of the ERP system. This leaves the need for purchasing typically transferred as purchase requests from Aptean EAM. In most of these cases, Aptean EAM ‘owns’ the spare part stock, though the stock control of the ERP system is also sometimes operated remotely from Aptean EAM. Seen from a user point of view, this leaves all functions used by floor level people to take place in Aptean EAM. The user won’t even notice that he or she is actually working in two systems.

Industrial Interfaces

OPC Client

Through the Industrial Interface module, Aptean EAM integrates with any kind of automation technology (control, visualization, process management, etc.).

The OPC technology allows for an online interface to be used in relation to maintenance of machines and equipment. With the integrated OPC client, Aptean EAM connects to an OPC server, making the information in the automation system available in Aptean EAM. No programming efforts are required to establish the connection, thanks to the standardized interface.

Condition Based Maintenance

The OPC connection can be used to collect data for condition monitoring measurements or for Aptean EAM Inspection Rounds system. It is also possible to collect operating time values for the production equipment here as well.

Compared to collecting the data manually, this saves a lot of time and makes it affordable to work with preventive maintenance intervals using ‘operation time’ rather than ‘calendar time.’ Here, the OPC connection helps you create a more predictive maintenance strategy by advising organizations to switch from ‘calendar time’ to ‘operating time’ based on preventive maintenance. This is the most important step towards increased availability of the production lines and reduced maintenance costs.

Furthermore, data in the automation system can be used to trigger alarms in Aptean EAM. If, for example, a temperature gets too high in a certain measurement point, Aptean EAM activates a pre-defined task as a new work order.

Boost Competitiveness and Production Efficiency With Aptean EAM and Internet of Things (IoT)

The Industrial Internet of Things, also predicted to be the fourth industrial revolution, is the time for the smart online factory. The goal is production with shorter adjustment and lead times, fewer errors and greater flexibility. With Aptean EAM you can take advantage of the IoT to increase your competitiveness.

Wireless sensors, used for condition monitoring, combined with modern IT solutions and analysis tools helps to predict patterns of equipment performance and condition.

Data from these “IoT services” are transferred to Aptean EAM via standard Internet protocols and creates automatic state-based work orders and unplanned stop are being registered.

Want to learn more about how Aptean EAM API PRO Edition can help your business? Contact us today to chat with one of our experts or schedule a demo. Also, discover our EAM Learning Academy for more EAM certified instruction. Register for a course today.

Ready to Start Transforming Your Business?

We’ve got the specialized EAM solutions you need to conquer your industry challenges.