Food and Beverage Supply Chain Resilience: Insights From Industry Experts

Food and Beverage Supply Chain Resilience: Insights From Industry Experts

Food and Beverage Supply Chain Resilience: Insights From Industry Experts

Jun 11, 2024

Aptean Staff Writer

Aptean Staff Writer

If you’re feeling the pinch of supply chain disruption in your food and beverage business, you’re not alone. A report from Willis Towers Watson that surveyed senior global decision-makers found a staggering 73% of companies in the industry have experienced higher-than-expected supply chain losses over the last two years.

Contributing factors such as climate change, labor shortages, geopolitical uncertainty, transportation delays and scarcity of materials often lead to missed sales opportunities, customer dissatisfaction and increased costs.

Building a resilient supply chain starts with a strong foundation of risk assessment. By proactively identifying and mitigating potential disruptions, you can minimize downtime and safeguard operational continuity. Robust contingency plans, paired with real-time data monitoring, can help your company quickly adapt to unforeseen challenges.

In our eBook Expert Roundtable: Supply Chain Resilience and Contingency Planning for Food and Beverage, six subject matter experts provide invaluable insights on best practices to help your business navigate supply chain uncertainties with confidence and precision.

This blog gives you a taste of what the full eBook offers. Meet the Aptean food and beverage industry experts and learn as they answer questions and provide actionable advice on supply chain resilience and contingency planning.

Supply Chain Resilience, According to the Experts

Our experts began by defining supply chain resilience. While the participants’ responses were varied, representing their unique perspectives, flexibility and business continuity during uncertain conditions were a common thread for each member of the panel.

Jack Payne stated that he thinks of “agility and being able to react to changes quickly” when he hears the phrase "supply chain resilience." “That starts with being able to identify the signs of change, and then being able to react to them,” he added.

For Daniel Erickson, being resilient means that one must expect such problems to happen. “You have to expect supply chain disruptions and have mitigation strategies in place to minimize [the impact] of these disruptions.” Meanwhile, Inge Vroonen emphasized that customer success ratio is critical in the beverage sector, “because there’s really high competition in the market.” Vroonen also mentioned the importance of flexibility for companies to efficiently deliver within tight timeframes while operating on thin margins.

Major Food and Beverage Supply Chain Challenges

As highlighted by our expert panel, the food and beverage industry faces a myriad of challenges, from material shortages to labor constraints. These disruptions—many of which were brought on by the pandemic—have exposed the vulnerabilities inherent in traditional supply chain models, necessitating a paradigm shift towards proactive risk mitigation strategies.

Vroonen also mentioned the war between Ukraine and Russia as an example of a major disruptor for the beverage market, as much of the glass production in Europe is done in Ukraine. “We’ve had several breweries in Belgium that just had to stop their production due to the scarcity of glass—they just didn’t have any more bottles,” she explained.

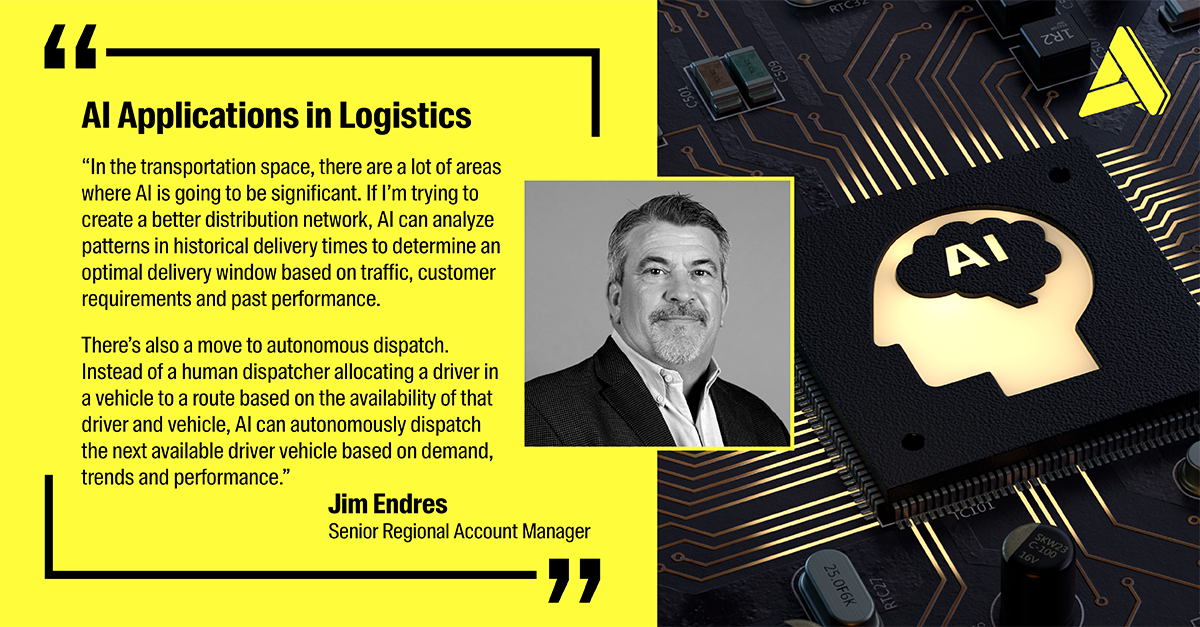

Jim Endres said if there’s a high demand for transportation, the cost goes up, much like what was seen during the COVID-19 pandemic. “The demand was so high and the supply—of vehicles, drivers and products—was so limited. So, the cost of everything was higher.”

Expert Strategies for Overcoming Supply Chain Challenges

In navigating the complexities of the modern supply chain landscape, food and beverage businesses must embrace innovative strategies to enhance resilience and mitigate risks effectively. The panel offered some valuable insights into key strategies for bolstering supply chain resilience:

Local sourcing and supplier diversification: Erickson advocated for exploring local sourcing options and supplier diversification strategies to mitigate risks associated with global supply chain disruptions.

Agile inventory management: Payne emphasized the importance of agile inventory management practices, including increasing on-hand inventory and alternative ingredient sourcing, to address material shortages and minimize production disruptions.

Forecasting and demand planning: Vroonen underscored the critical role of forecasting and demand planning in driving supply chain resilience, enabling your business to anticipate market fluctuations and optimize production schedules accordingly.

Technology integration and data-driven decision-making: Gareth Evans highlighted the transformative potential of technology in bolstering supply chain resilience, emphasizing the importance of data-driven decision-making and advanced analytics in optimizing fleet operations and last-mile delivery processes.

In addition to these strategies, our subject matter experts also provided deeper insights into how technology solutions, such as food and beverage-specific enterprise resource planning (ERP) software and transportation management systems (TMS), including routing and scheduling software, can further enhance supply chain resilience.

Find out more about how your food and beverage business could achieve supply chain resilience. Download your free copy of the eBook, Expert Roundtable: Supply Chain Resilience and Contingency Planning for Food and Beverage, today.

Ready to start transforming your food business?

We’ve got the specialized TMS solutions you need to conquer your food logistics and distribution challenges.