Load Planning Software 101: Efficiency, Accuracy and the Power of AI

Load Planning Software 101: Efficiency, Accuracy and the Power of AI

Load Planning Software 101: Efficiency, Accuracy and the Power of AI

Jun 24, 2025

Bethany Sanders | Digital Marketing Content Writer

Bethany Sanders | Digital Marketing Content Writer

As a logistics professional, you know that space is physical as well as financial. Every square inch in a trailer, container or cargo hold costs money—in fees, fuel, labor, equipment and missed opportunities—so wasting it isn’t an option. That’s why companies like yours are investing in intelligent load planning software—to pack more, spend less and streamline logistics.

Whether you're shipping goods by road, sea or air, load planning in logistics has come a long way from spreadsheets and guesswork. The best load planning software helps you fill space smartly with speed, precision and in the best systems, a little help from artificial intelligence (AI).

If you're still using spreadsheets, free online load calculators or outdated tools, you're missing out on serious efficiency—and likely leaving dollars on the table.

Let’s break it down.

What Is Load Planning Software and What Does It Do?

At its core, load planning software helps you find the most efficient way to organize, arrange and pack cargo in a transportation vehicle or container. Think of it as a digital architect for your shipments—one that balances weight, dimensions, regulations and delivery requirements—all without giving your operations team a headache. Advanced platforms can even account for non-rectangular items and internal truck features like wheel arches.

Gone are the days of playing virtual Tetris with boxes and hoping the last pallet fits. Modern load planners do more than just stack items. They calculate and visualize. The smartest ones even use AI to factor in your unique business rules, shipping constraints and cargo types.

Here’s what the best solutions offer:

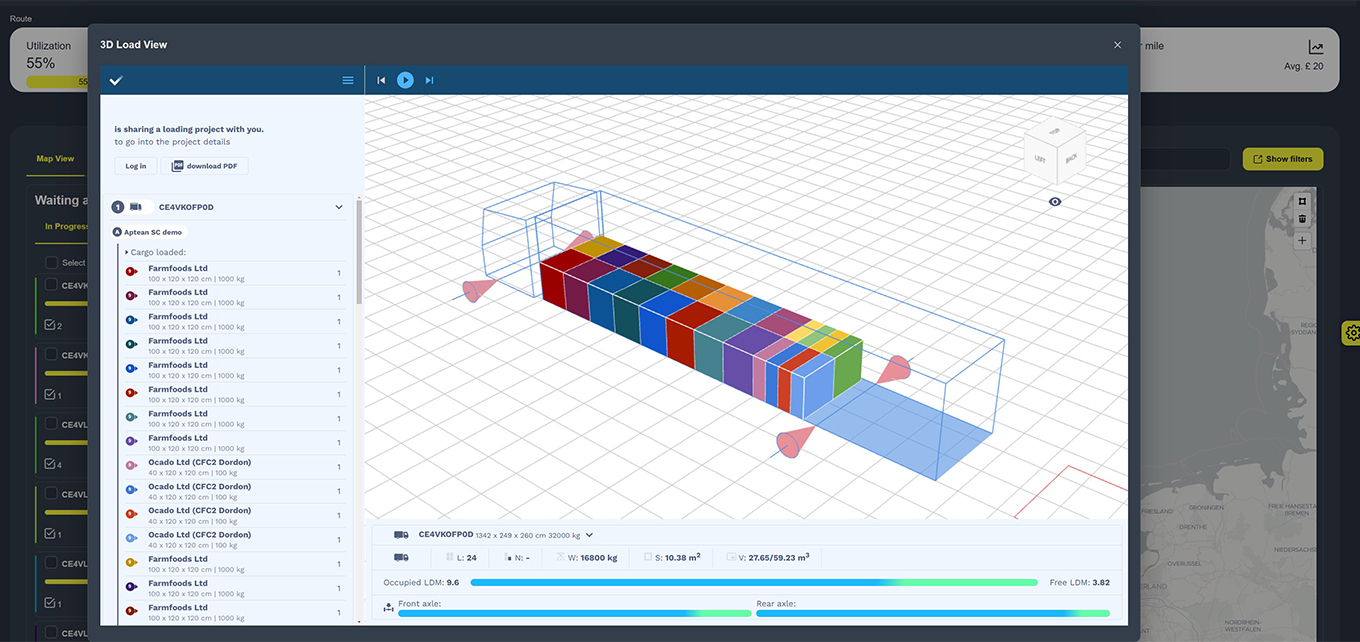

3D Load Visualization: Understand exactly how a load will fit in each vehicle with interactive, real-time 3D renderings. This reduces trial-and-error during physical loading and cuts down time at the dock.

Custom Stacking and Weight Distribution Rules: Define how goods can and cannot be placed—fragile on top, liquids upright, heavy items low and forward. The system applies these rules across all shipments, ensuring consistency and safety.

Multimodal Compatibility: Adjust load plans to match the constraints of each transport mode, whether you're using truck load planning software for 53-foot dry vans or container load planning software for 20-foot ocean containers.

Palletization Logic: Automatically build mixed-SKU pallets with the right stacking sequence. Useful for retail and foodservice suppliers where product arrangement affects restocking efficiency.

Weight Distribution Checks: Prevent overweight fines and axle imbalance issues by ensuring compliance with Department of Transportation (DOT) and international standards.

API Integrations: Connect your enterprise resource planning (ERP) system, warehouse management system (WMS) or transportation management system (TMS) for real-time data syncing. Orders, inventory and customer details can be pulled in automatically, eliminating manual entry.

Dynamic Optimization With AI: With advanced solutions, you can utilize dynamic optimization powered by AI, unlike spreadsheet-based systems or free load calculator tools. This AI-driven adaptability ensures your shipments are tailored, not templated.

What Are the Benefits of Load Planning Software?

If you're wondering whether the investment is worth it, let’s talk about what you actually gain.

1. Significant Cost Savings

Optimized load planning in logistics means fewer shipments, reduced fuel usage and maximum use of available space. By minimizing partial loads and avoiding inefficient less than truckload (LTL) shipments, you can cut your transportation spend significantly. You also sidestep overage fines and trim packaging costs by reducing the need for dunnage like risers and airbags.

2. Time Savings Across the Board

With AI-powered load planning, what used to take hours in Excel takes just minutes. Schedulers can auto-generate multi-stop loads, select the best-fitting equipment and instantly visualize options with clear 3D visuals—no more manual math or trial-and-error. When load planning software is integrated with your other systems, you eliminate back-and-forth between teams by automatically syncing details from your ERP, TMS and WMS. Faster planning also speeds up loading dock operations; staff get clear, step-by-step loading instructions, which means fewer delays and a tighter delivery schedule.

3. Improved Safety and Compliance

Breaking safety rules or not following regulations can cost you money—and it puts your cargo, crew and reputation on the line. The best load planning software ensures that weight is distributed properly, cargo is stacked according to custom rules, and each load adheres to regional and international transport regulations. Whether you're shipping liquids in intermediate bulk containers or fragile packaged goods, the system prevents top-heavy stacks and protects high-risk items, reducing the risk of damage or on-road incidents.

4. Less Labor, More Output

Manual planning requires time and experience while resulting in a high margin for error. Instead, load planning software helps cuts down the labor hours needed to build effective plans and reduces dependency on tribal knowledge. With intuitive visuals and drag-and-drop tools, even new hires can plan loads like seasoned pros—boosting productivity and reducing errors. This way, your team gets more done with less effort—and fewer mistakes.

5. Better Customer Service Outcomes

Load planning directly impacts delivery reliability. Smart planning enables tighter schedules, fewer delays and a lower risk of cargo damage—especially critical with time-sensitive or fragile goods like food or electronics. Loads can be sequenced by delivery order for smoother drop-offs, helping ensure every customer gets what they ordered, when they need it, in perfect condition.

6. Operational Efficiency and Scalability

At its core, load optimization is about doing more with less. Fewer pallets, tighter stacks and smarter use of every cubic inch lead to better warehouse space utilization and reduced need for extra trucks or staff. This isn’t just about cost savings—it’s how you build a more scalable, resilient logistics operation that can flex with seasonal peaks, rising demand or tighter margins.

Why It’s Best To Use a TMS With Built-In Load Planning

Online cargo load planners and free container load planning software might sound convenient, but they’re not designed to handle the complexity of real-world logistics. They don’t know your business, your delivery windows, your carrier preferences, vehicle availability or your product sensitivities. They’re static tools trying to solve dynamic problems.

That’s why an integrated TMS with built-in load planning software makes all the difference.

Your data is already there: Your TMS already houses your business rules, equipment specs, customer preferences and routing constraints, so you’re not wasting time re-entering data or manually juggling multiple systems. Instead, the load planner taps into existing information to instantly generate optimized, compliant plans that align with your operations.

AI-driven optimization: You get access to powerful AI-driven capabilities that go far beyond what basic tools offer. Rather than applying rigid templates, these systems use your data and constraints to build better plans faster—so that you get the best possible use of space and resources every time.

Full-suite functionality: An integrated TMS handles much more than just load planning, with carrier selection, freight auditing, rate shopping, dock scheduling and more included. This offers a complete range of benefits—streamlining your entire logistics workflow, further cutting costs and improving overall service.

An integrated system: When everything lives in one system, you avoid duplicate data entry, reduce errors and keep your entire team on the same page. This also means you get performance metrics and optimization reports that help you make data-driven improvements over time.

Load planning isn’t just better inside a TMS—it’s smarter, faster and far more scalable.

Start Planning Smarter Loads and Strengthen Operations With Aptean TMS

AI-driven load planning is a cornerstone of modern logistics efficiency. With 3D load visualization, dynamic optimization and seamless integration into your broader systems, you can load smarter, reduce costs and deliver with confidence.

Aptean’s TMS includes a built-in 3D load builder, powered by AI, that makes this possible. With our software, you can fit more product into each load, reduce equipment needs, speed up warehouse operations and use fewer pallets—while improving safety and minimizing damage risk.

And because it’s part of our fully integrated, cloud-based TMS, you get benefits that extend beyond the trailer, including better route planning, real-time visibility and end-to-end freight management.

If you’re looking to boost your logistics performance, reduce costs and simplify operations, it’s time to explore what smarter load planning—powered by Aptean—can do for you.

Take a self-guided tour of our TMS now or schedule a personalized demo with one of our experts to see the difference intelligent optimization can make.

Unlock the Value of Your Logistics Operation With Aptean TMS Solutions

Book a demo at a time that suits you and discover how you can run a leaner logistics operation—with fewer surprises and more control.