88% of Manufacturers Still Experiencing Long Supplier Lead Times

88% of Manufacturers Still Experiencing Long Supplier Lead Times

88% of Manufacturers Still Experiencing Long Supplier Lead Times

Jan 17, 2022

Andy Pickard | Senior Solutions Consultant, Sales

Andy Pickard | Senior Solutions Consultant, Sales

Supply chain disruption has been a major challenge for manufacturers over the last year, and delays are far from resolved. 88% of North American manufacturing companies are still experiencing longer-than-usual lead times, according to new Aptean research.

We surveyed 275 manufacturers about their current supplier capabilities for a new whitepaper on supply chain management. And while our research found the landscape is improving, supplier lead times still aren’t back to normal—particularly in discrete manufacturing, where 1 in 5 organizations say lead times are getting worse.

How Are Supply Chain Challenges Impacting Customer Relationships?

While 78% of manufacturers predict higher sales and revenue performance in 2022, as revealed in our 2022 manufacturing industry forecast, overcoming supply chain disruption will prove critical to hitting these targets.

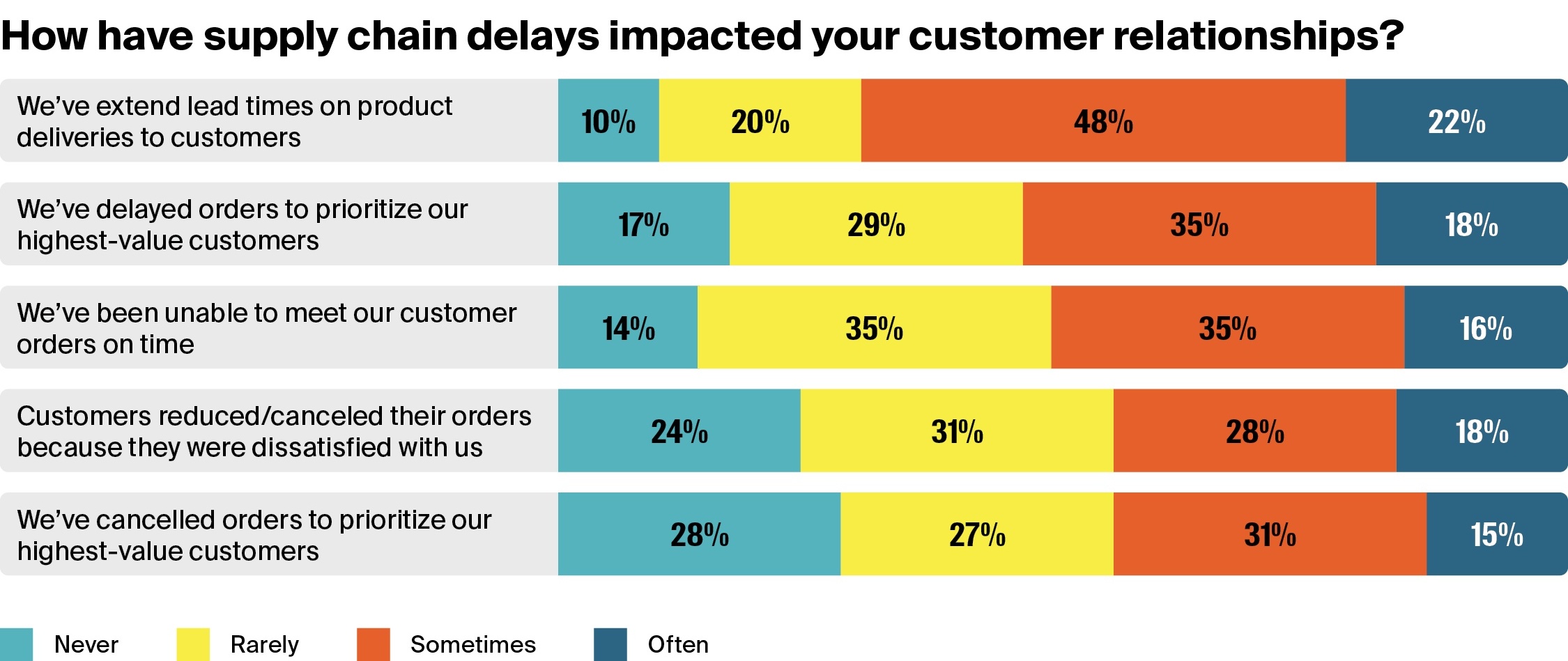

Concerningly, supply issues are currently impacting manufacturers’ ability to meet customer demand, with 70% of organizations regularly extending product delivery times as a result of material delays.

Tough decisions have also been made when components or ingredients are in short supply: 45% of discrete and process manufacturing companies have admitted to cancelling some orders to prioritize their highest value customers.

When it comes to managing customer relationships, it’s not just extended lead times that manufacturers are contending with either. Unstable material costs have markedly impacted profit margins, with 4 in 10 manufacturing organizations claiming price fluctuations have been their biggest supply chain challenge of 2021.

If you’re wondering how your organization’s supply chain strength compares to other manufacturing companies, download our new whitepaper, Chain Reaction: How Manufacturing Supply Improvements Will Grow Customer Relationships to find out.

Understanding the causes of disruption is an important step towards making strategic supply network improvements. But rather than fixate on where manufacturers have struggled this year, we need to look at how industry leaders are successfully navigating their supply chain struggles, to give manufacturing companies a framework for stronger supplier management in 2022.

How Is Technology Investment Enhancing Supply Chain Management?

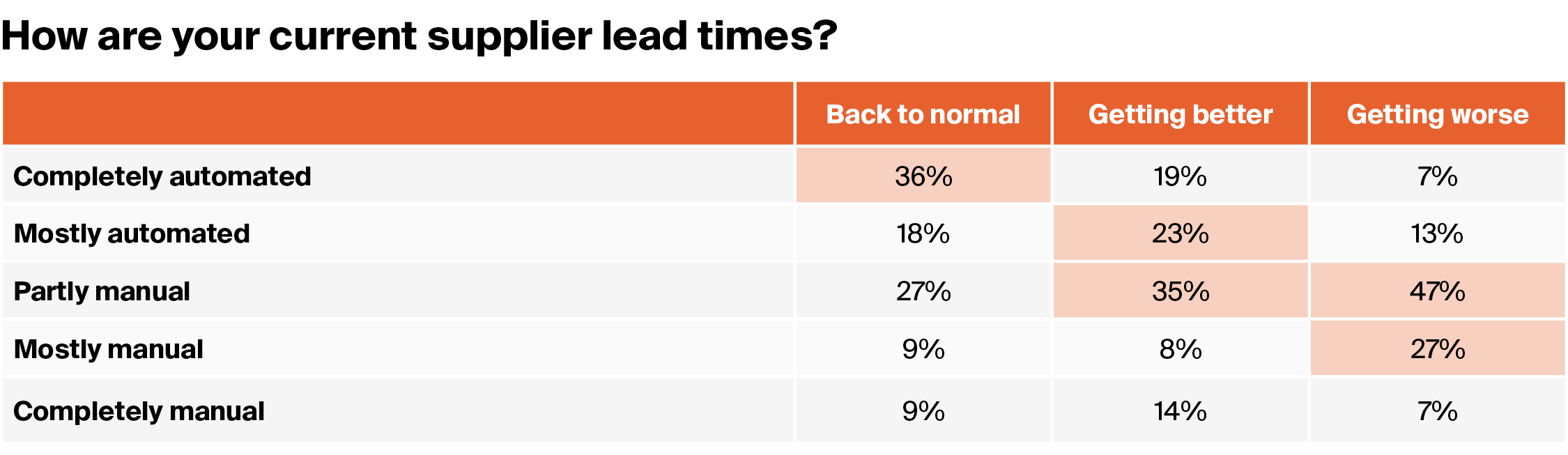

One clear finding from our manufacturing research is that supply chain automation is a performance game-changer.

While 68% of manufacturers are still relying completely or partly on manual processes to coordinate supplier relationships and control inventory, manufacturing companies with back-to-normal lead times are more likely to be in the advanced stages of digital transformation.

When it comes to successful supply chain automation projects, manufacturers’ current investments have focused on improving contingency planning, building up inventory, and making smarter use of that inventory by improving production scheduling. Half (54%) have also invested in software to improve supply chain visibility.

Even among manufacturers that haven’t yet digitized their supply chain management, there is widespread recognition of the benefits automation can deliver: 98% of organizations we surveyed said investing in supply chain technologies is important to reach their future business goals.

Within companies that are planning to implement supply chain management software over the next 12 months, their key priorities are improving forecasting abilities, streamlining the supplier onboarding processes, and being able audit supply networks to understand current vulnerabilities.

How Can Manufacturing Supply Chain Automation Mitigate Market Disruption?

Looking at technology objectives among both manufacturers in the advanced stages of supply chain transformation and those that are still at the planning stage, our research revealed some common objectives. Organizations want greater clarity over their operational data, along with the technical agility to make accurate decisions based on real-time information.

Supply chain management is unique in that it’s extremely vulnerable to external forces. As we’ve seen from global events like the pandemic, extreme weather and international policy changes, diverse factors beyond manufacturers’ control can lead to material delays, supplier availability problems and extended delivery times.

Read more: 6 Global Events that Have Disrupted the Manufacturing Supply Chain.

And while supply chain management technologies can’t prevent wider market problems, they give manufacturers quicker, better data insight on how they will affect customer orders—so they can make decisions that contain their overall business impact. And they also enable rapid, automated action that helps to mitigate disruption.

Aligning Manufacturing Software Investment With Digital Transformation Goals

While we hope supplier lead times will continue to normalize, that definition of ‘normal’ is vastly different to 18-24 months ago. The manufacturing supply chain feels more vulnerable to upstream disruption than before, but manufacturers are taking control of unknown variables through supply chain management software.

To drive success in 2022, the critical objective for manufacturers will be integrating that software investment into their wider digital transformation strategy, to ensure it drives noticeable business improvements.

For example, organizations in the early stages of digital transformation will gain hugely from basic process automation, increasing operational efficiency and generating accurate operational data. Whereas those in the advanced stages of digital transformation can improve material requirement planning by aligning supplier information with production scheduling and order forecasting. Digitally advanced manufacturers may even be at the stage of predictive modelling market scenarios to strengthen their supply chain strategy.

Whatever their stage of digital maturity, with the right manufacturing software investment, organizations can use supply chain management changes to drive business-wide improvements. So fluctuation in material costs and availability no longer disrupt manufacturers’ abilities to deliver on customer demands.

Download your free copy of Aptean’s new whitepaper, Chain Reaction: How Manufacturing Supply Improvements Will Grow Customer Relationships. Or contact our manufacturing industry experts to discuss how the right technology can help your digital transformation progress.

Start Transforming Your Business Today

If you’re ready to take your discrete and industrial manufacturing business to the next level, we’d love to help.