Featured in this post

Top 6 Sustainable Fashion Strategies for Your Brand

Top 6 Sustainable Fashion Strategies for Your Brand

May 2, 2024

Aptean Staff Writer

Aptean Staff Writer Blog Post

Quick Glance At the Key Takeaways

Growing demand for eco-friendly brands makes sustainability a key competitive advantage. The following strategies help you capture the opportunity and build a responsible and future-ready fashion business:

Choose eco-friendly materials and work with eco-conscious suppliers.

Shift to eco-friendly production processes, including using natural fabrics and dyes, recycling water and identifying pollution risks.

Employ technology—apparel ERP, PLM, transportation tools and AI—to optimize materials, planning, distribution and transparency.

Optimize production planning to reduce waste.

Keep an eye on your energy and water usage to reduce costs and environmental impact.

Dive in for more details on these strategies and the trends driving them.

The fashion industry is undergoing a green revolution. Consumers today are increasingly prioritizing sustainability, demanding transparency about a brand's practices and environmental impact. This shift creates a golden opportunity.

According to a report by Coherent Market Insights, the Global Sustainable Fashion Market size was valued at $7.80 billion in 2023 and is expected to reach $33.05 billion by 2030. By prioritizing fashion sustainability in your business, you'll naturally attract consumers in this growing and loyal market segment and can grab your slice of that very appealing pie.

In addition, sustainable practices in fashion often lead to operational improvements. Reducing waste, using recycled materials and minimizing energy consumption can streamline your production process and potentially cut costs. In short, by going green, you're not just helping the planet; you're also investing in the future of your brand.

But, how do you go about implementing environmentally friendly practices at your business without sacrificing efficiency or hampering day-to-day operations? To help you get started, we’ll discuss some of the biggest sustainable fashion trends and provide six key strategies that you can implement right now. And finally, we’ll touch on how technology, including apparel-specific enterprise resource planning (ERP) software and artificial intelligence (AI) tools, empower you to deliver cost-effective change in your business.

Keep reading to learn how to navigate the exciting world of sustainable fashion.

Sustainability Trends in Fashion That Are Shaping the Future of the Apparel Industry

With 73% of millennials willing to pay extra for items from sustainable brands and around 75% of Gen Z consumers having bought used clothing to reduce their environmental impact, the growth potential of this sector is becoming more and more apparent.

As such, leaders in the market are responding with a concerted effort to minimize environmental impact and promote eco-friendly practices. Here are eight of the biggest sustainable fashion trends poised to redefine the industry in the coming years.

1. Circular Fashion

This trend emphasizes the recycling and reusing of sustainable fabric to create new garments, thereby reducing waste and conserving resources. In a 2022 Bloomberg report, 11.3 million tons of textiles were thrown away each year—around 2,150 pieces of clothing each second in the U.S. alone. To minimize this excessive waste, circular fashion involves designing products with their entire lifecycle in mind, ensuring that they can be easily repurposed or recycled at the end of their use.

2. Eco-Friendly Materials

The use of sustainable textile materials is becoming more prevalent. Organic, biodegradable, recycled and eco-friendly fabrics such as organic cotton, hemp and recycled polyester are gaining popularity. These materials reduce reliance on non-renewable resources and minimize the environmental impact of production.

3. Slow Fashion

Slow fashion is one of the key sustainable trends in fashion and it advocates for quality over quantity, encouraging consumers to buy fewer, higher-quality items that last longer. This movement contrasts sharply with the fast fashion model, which promotes rapid production and consumption of low-cost garments.

4. Technological Innovations

Advances in technology are driving sustainability in fashion. Innovations such as lab-grown leather, 3D printing, digital design tools and apparel software solutions, including the aforementioned ERP and product lifecycle management (PLM) systems, help reduce waste and resource consumption.

For example, a dedicated fashion ERP integrates and streamlines business processes across the entire fashion supply chain, from design and material sourcing to production, inventory management and distribution. This allows apparel companies to:

Improve demand forecasting for more accurate production planning and reduced overstock and waste.

Optimize material usage by tracking materials throughout production process and minimizing waste.

Enhance transparency in the supply chain to enable businesses to identify and source sustainable materials and partners.

5. Truth in Traceability and Transparency

With consumers increasingly concerned about the environmental and social impact of their clothing, they want to know exactly where their clothes come from and how they were made.

Apparel software solutions support this accountability and allow:

Traceability - brands can track the journey of a garment, from the raw materials to the finished product. This information can then be shared with consumers, giving them the confidence that their clothes are being produced ethically and sustainably.

Transparency - goes beyond traceability, encompassing clear information sharing about all business aspects, including the working conditions in factories, the use of chemicals and the overall environmental footprint of production processes.

By prioritizing traceability and transparency, brands can build trust with consumers and demonstrate their commitment to sustainability. This shift towards openness can differentiate your brand in the crowded market.

6. Sustainability Reporting

Effective sustainability reporting is vital for brands to communicate their sustainability efforts and achievements to all stakeholders. Not only are these practices critical for regulatory compliance, but they are also important in creating a transparent corporate culture that engages employees in driving toward environmental and ethical goals.

Detailed reports that outline a company's sustainability goals, actions and progress can play a significant role. These reports often include metrics on energy use, carbon emissions, water consumption and waste reduction.

7. Engaging Narratives and Storytelling

Sharing stories about sustainable practices, collaborations with eco-friendly partners and the positive impacts of these initiatives can help build consumer trust and differentiate brands in a competitive market. These narratives can humanize a brand and make its sustainability efforts more relatable and compelling.

With around 48% of consumers admitting they don't know where to find sustainable brands, ensuring your sustainability credentials are front and center in marketing and branding campaigns could help you capitalize on this burgeoning market before the competition.

8. Customer Education and Engagement

Educating and engaging customers is essential for fostering a culture of sustainability. Leading brands in this sector are employing various strategies to inform and involve their customers, including:

Innovative Transparency - While clear packaging and labeling are essential for product transparency, leaders can leverage visual content such as videos, infographics and social media posts to transform complex information into engaging and easily digestible formats.

Interactive Platforms - Creating online platforms where customers can learn about sustainable practices and track the sustainability of their purchases. These platforms can include educational resources, calculators and personalized recommendations.

Community Involvement - Encouraging customers to participate in sustainability initiatives, such as recycling programs, environmental campaigns and community events can foster a sense of shared responsibility and collective action.

of the global carbon dioxide output is produced by the fashion industry.

Effective Sustainable Fashion Strategies For Your Business

As these trends make clear, sustainability in fashion and apparel businesses is becoming increasingly essential to reduce environmental impact, comply with regulations and meet consumer demand for eco-friendly products.

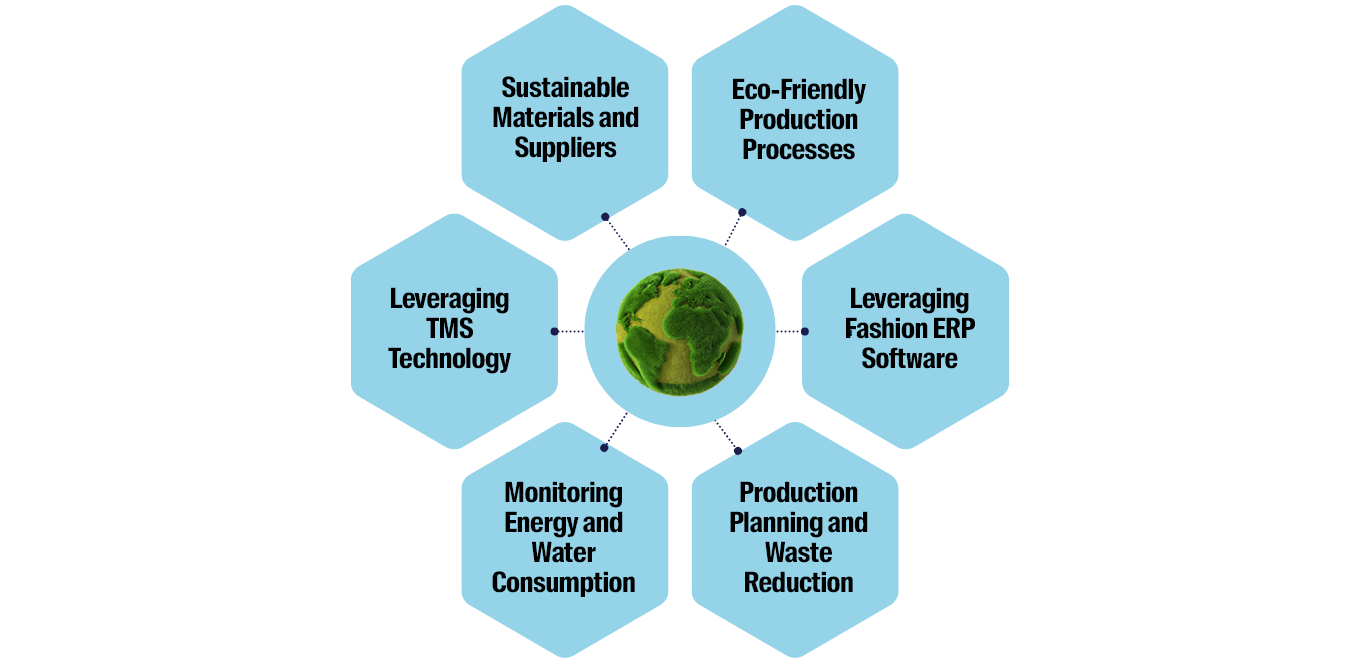

Below are six immediate strategies for incorporating sustainable practices into your operations.

1. Choosing Sustainable Materials and Suppliers

Adopting sustainable and eco-friendly materials is critical for reducing the environmental footprint of your products; examples of such materials include organic cotton, recycled polyester and Tencel.

Which materials will be best for your business will vary, but you’ll need to consider the type of product or design, the distance materials can be sourced from, emissions involved in creating them and material life cycle analysis (LCA). You may even want to explore how environmentally friendly the smaller details on your products are, such as zippers, buttons, labels and trim—all of which have more sustainable options available.

Partnering with suppliers who have strong sustainability credentials ensures that your entire supply chain adheres to eco-friendly practices. To get started, you’ll need to clarify your company standards to ensure you only select suppliers that prioritize the same practices and commitments that are important to your business.

Then, to evaluate candidates against those standards you can request their environmental and social responsibility policies, check their compliance with applicable regulations and look for certifications such as Fair Trade, Global Organic Textile Standard (GOTS) and Forest Stewardship Council (FSC).

2. Implementing Eco-Friendly Production Processes

Adopting green manufacturing processes can significantly reduce the environmental impact of production. This includes using non-toxic dyes, choosing natural cloth materials, recycling water in production and reducing emissions. Technologies like closed-loop manufacturing systems can also help in minimizing waste and maximizing resource efficiency.

Here are some practical steps you can take to implement these strategies in your business:

Analyze your material usage, energy consumption and waste generation to identify areas for improvement.

Regularly track your emissions, discharges and waste disposal practices.

Proactively identify and address any potential pollution risks to safeguard the environment and local wildlife.

Consider investing in closed-loop systems, energy-efficient machinery and look for available grants or rebates.

Train your team on waste reduction and responsible resource use to empower eco-friendly choices.

3. Leveraging Fashion ERP Software

Technology plays a pivotal role in driving sustainability within the fashion sector. Advanced fashion ERP systems leverage cutting-edge technologies such as artificial intelligence (AI), big data analytics and the Internet of Things (IoT) to optimize resource use and minimize waste.

An AI-enabled ERP designed for fashion and apparel is a great place to start as it facilitates:

Enhanced Inventory Management - Effective inventory management helps you align your production with customer demand, reducing the risk of overproduction or shortages. An ERP system can enhance inventory tracking and forecast demand accurately, while AI-powered predictive insights strengthen your planning accuracy, so you can keep stock levels balanced and prevent waste.

Supply Chain Management (SCM) - Choosing ERP software combined with electronic data interchange (EDI) and an in-built vendor management portal helps you track suppliers, improve collaboration and manage sustainability guidelines, certifications and audits. Meanwhile, AI and ERP automations such as agentic agents can make supplier communication and documentation processes easier, help you spot compliance issues or conflicts in sustainability approaches quickly.

Data-Driven Decisions - When you choose an apparel ERP that’s part of a connected AI platform, like Aptean AppCentral, your business data is now connected seamlessly end-to-end. This means you get predictive insights to identify opportunities, and even non-technical users can easily query data using AI-powered natural language searches. What’s more, real-time data visibility and key performance indicator (KPI) reporting helps you monitor compliance with sustainability practices and highlight areas for improvement.

Cost Savings and Efficiency - By automating processes and streamlining workflows, am AI-enabled fashion ERP platform helps reduce the day-to-day cost of doing business and improves overall operational efficiency. Moreover, AI-driven workflow automation and data analysis help you maximize resource utilization and reduce waste which positively impacts the environment, and free up funds for new sustainability initiatives or campaigns.

4. Optimizing Production Planning and Waste Reduction

Effective production planning can minimize waste and overproduction. Techniques such as lean manufacturing and just-in-time (JIT) production help in optimizing the use of materials and reducing excess inventory; regular audits can further enhance efficiency and sustainability.

Implementing and optimizing these strategies requires a central nervous system for manufacturing operations. ERP software integrates all your production data, from inventory levels and material requirements to machine capacity and workforce scheduling.

This real-time visibility allows you to:

Plan more accurately

Reduce waste and overstock

Improve resource allocation

Automate repetitive tasks

5. Monitoring Energy and Water Consumption

Monitoring and managing energy and water consumption are vital for reducing operational costs and environmental impact.

To achieve sustainability goals, consider these ways:

Smart meters and energy management systems provide real-time data to identify areas for improvement in energy consumption.

Investing in renewable energy sources like solar or wind power contributes to sustainability goals.

Upgrading to water-efficient technologies helps conserve water and promotes sustainability.

6. Leveraging TMS Technology To Reduce Mileage and Emissions

Whether you’re running your own fleet or outsourcing distribution, it’s important to consider the environmental impact of delivering your products. Even if you’re creating fantastically sustainable items, unnecessary truck miles and fuel consumption can undo all that hard work by increasing carbon emissions. Transportation management solutions help you reduce these impacts in several ways. Let’s start with businesses that are using carriers and third-party providers to deliver apparel shipments. Here, transportation management systems (TMS) can help identify the best carriers and vendors by comparing performance, cost, delivery reliability and even their sustainability efforts—ensuring your partners align with your environmental goals. In addition, 3D and AI-enhanced load planning capabilities ensure you’re using your vehicle space efficiently so every trip can carry more, reducing unnecessary travel and cutting emissions. For businesses with their own fleet of vehicles, AI route optimization tools transform route planning processes with advanced machine learning algorithms and AI assistants that learn as you go. This helps you reduce mileage, cut fuel costs and lower emissions—ensuring you can minimize the carbon footprint of your distribution network. Adding an electronic proof of delivery (ePOD) system to your logistics tech stack also supports your sustainability goals by eliminating paper-based processes and reducing manual administration. Shifting to digital delivery records ensures your organization can operate more responsibly and strengthen your reputation as environmentally conscious at the physical point of delivery.

Building a Greener Future for Fashion With Aptean Apparel Software

As we’ve seen, innovative trends, transparency and technology are the cornerstones of building a successful, sustainable fashion brand. But environmental responsibility is not just about materials or design—it depends on how efficiently your entire operation runs. That’s where Aptean helps you turn responsible practices into everyday reality. Our AI-powered connected workspace, Aptean AppCentral, unifies all your industry-specific apps and gives you access to a powerful layer of AI capabilities to improve visibility, efficiency and automation across your entire operation. With a modular approach and straightforward implementation processes, you’re able to start with the tools you need and expand or adapt as your business grows. For example, our industry-tailored ERP for fashion and apparel brands strengthens planning, reduces waste and gives you clear visibility across your supply chain. allowing you to identify and source sustainable materials and partners, and ensure complete transparency for your customers. Meanwhile, with our range of transportation software, including our AI-enabled routing and scheduling software, you cut fuel use, avoid unnecessary miles and choose carriers that align with your environmental goals. Inside your facility, our award-winning shop floor control software improves worker morale by simplifying daily tasks, removing manual steps and giving teams real-time clarity so they produce with fewer errors and less waste. Plus, our apparel PLM supports responsible development by improving early prototypes, reducing rework and preventing material loss long before production begins. And the real advantage? You don’t need multiple disconnected tools to achieve all this. With AppCentral, every system is brought into one secure and seamless platform, bringing every invoice, every user and every data point together—all powered by Aptean Intelligence. With this end-to-end visibility and automation you’re able to optimize every stage of your fashion operation enhancing efficiency, reducing resource consumption and minimizing your environmental impact.

Take fashion to the next level, ethically and sustainably, with our apparel software—streamlining your operations saves you money while empowering you to be a leader in eco-conscious practices.

Get in touch with our experts today to schedule your personalized demo.

Ready to Transform Your Fashion and Apparel Business Today?

If you’re ready to take the next step, we’d love to help.