The Paragon Customer Q&A: Automating Route Planning at Colorado Boxed Beef Company

The Paragon Customer Q&A: Automating Route Planning at Colorado Boxed Beef Company

The Paragon Customer Q&A: Automating Route Planning at Colorado Boxed Beef Company

Feb 11, 2020

Colorado Boxed Beef Company (CBBC) is a major distributor of refrigerated and frozen meat, cheese and other food products, with corporate headquarters in Lakeland, FL. CBBC’s branded product lines include High River Angus beef and Diamond Reef seafood. Customers range from supermarkets and restaurants to cruise companies, military bases and schools. Grant Hoppie joined CBBC in March 2018 as Transportation Manager for its Dallas-based facility. He was previously Dedicated Transportation Manager at Ruan Transportation Management Systems.

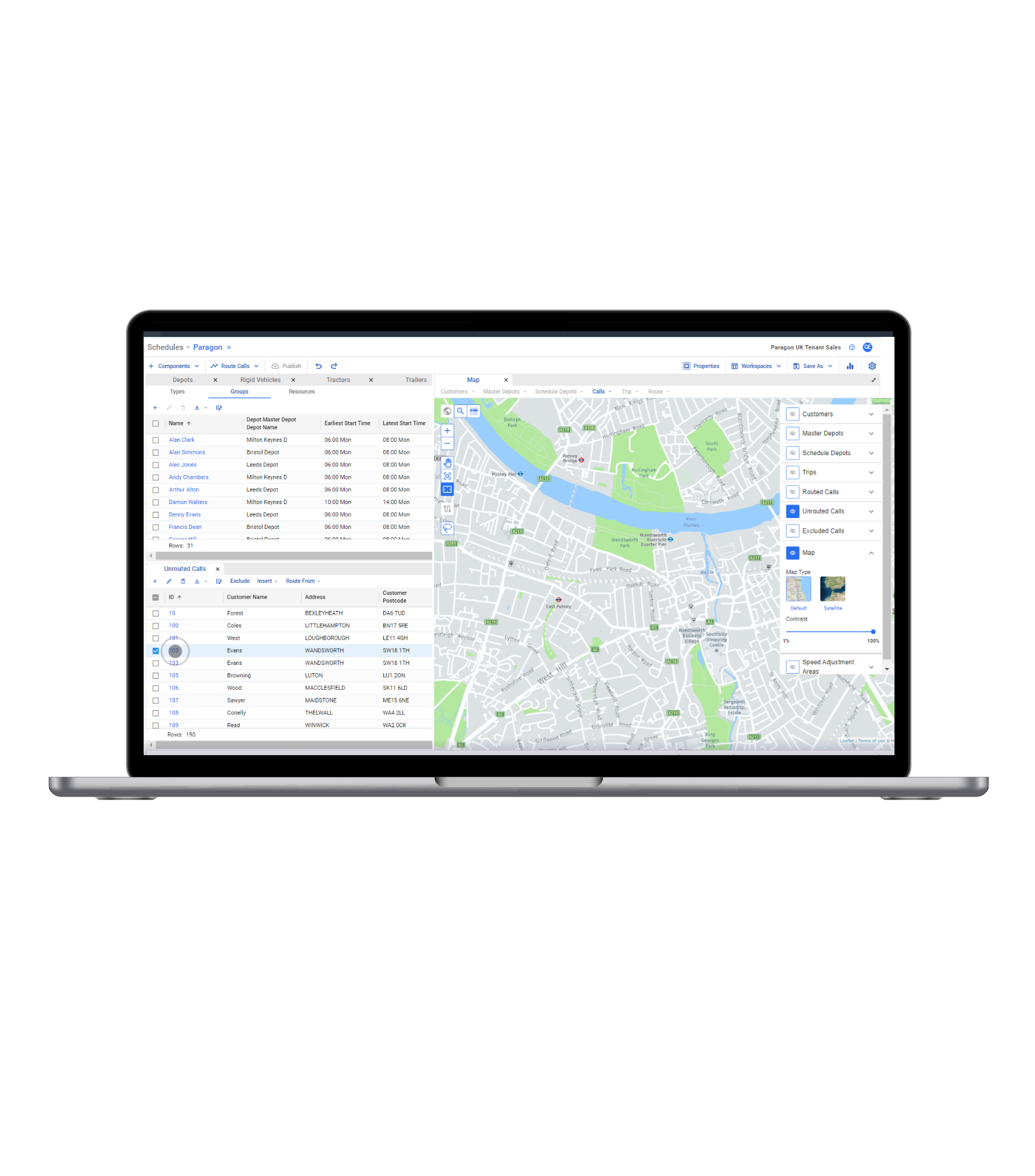

CBBC expanded implementation of Paragon from Aptean's route planning software across its operations in July 2018, in order to increase efficiency for more than 6,000 deliveries per week, using approximately 180 tractors and 220 drivers. It has since added Paragon from Aptean's Route Execution software to connect the route planning software with CBBC’s telematics system, allowing real-time tracking of delivery vehicles across the network, among other benefits.

Q: Who are your customers, and what is important to them when working with CBBC?

A: We have a wide variety of customers that operate a very diverse range of businesses. In terms of needs, however, those are not too different. Most customers expect the same, high amount of satisfaction. Timing of deliveries is the most important factor, but good service also means drivers who understand what the product is, are respectful to customers, and go out of their way to take care of the customers. For example, they know which products need to be delivered straight into the freezer.

Q: How has customer demand evolved in the food industry, and what has that meant for your distribution and delivery operations?

A: Customer demand in the food industry has evolved much as it has elsewhere in these days of an “Amazon” culture. They absolutely expect products to be delivered in the shortest time after ordering, with better rates. It’s not quite at the level of free delivery, but we are offering same-day delivery for certain customers. Most of the time, it’s next-day delivery.

We’re also responding to demands for more frequent, more proactive communication. Customers need accurate time windows, and information about exactly when we’re arriving. The good news is, we have so many methods of communication now, especially with the automated route planning system, it’s very simple. And a handful of our customers love that we have the ability, via the route execution software, to be able to track where driver is and when they’ll arrive. In general, we now have the ability to send out a message via email or other format to let them know when a delivery will arrive, so the customer’s location can be staffed properly.

I think society as a whole expects more for less, it’s just what we’ve grown accustomed to. That can really drive up costs if you’re not careful.

Q: What is your biggest delivery operational challenge?

A: The real challenge on both a day-to-day and strategic basis is handling one-off requests from the sales department or from customers for uniquely timed deliveries for the following day. Some days, we get 10 or 15 of these, so instead of the existing route plan, we have to go in and change things to meet a very small time window. That’s really the largest challenge.

"The impact of technology has been huge. I’d say monumental! For me personally and for our company, delivery operations have changed drastically, from a manual to a fully automated approach, which has had an impact that can’t be quantified."

Q: What part has technology played in changes to your delivery operations?

A: The impact of technology has been huge. I’d say monumental! For me personally and for our company, delivery operations have changed drastically, from a manual to a fully automated approach, which has had an impact that can’t be quantified. We have hugely increased confidence that we are offering our customers close to 100 percent satisfaction. We used to receive a decent number of complaints from customers who were not happy with delivery times and many other factors, and we simply do not hear that any more. With automated route planning, we can work much more efficiently—with drivers, tractors, trailers and all our resources. We can do so much more with much less.

Q: What are the downsides of introducing automated route planning?

A: There’s maybe one, and that is the effort needed to break old habits, including retraining people to accept that planning routes from now on is going to be easier and much more manageable. This is a change that needs to happen not just in the planning team. Truthfully, it’s across the board. There is something of a learning curve. Funnily enough, I was expecting negative feedback from the drivers, because they were used to static routes and now we were changing that up. But, when we launched with automated route planning, we never received the negative feedback that I anticipated. They said it made so much sense! Our customer service department had to get used to change, too. It’s got to the point where, if we do get a request from a customer, it’s because they’re changing location or delivery times—there are no negative complaints.

Q: What are the benefits? Are there specific KPIs you have measured and/or will measure?

A: We do track metrics in our Dallas and Oklahoma City facilities, where we measured performance when we were routing manually, to use as baseline KPIs. But keeping track of the metrics is challenging, because when routing became so much more efficient, we grew exponentially. We’ve made a major expansion to our geographic footprint and added 1,200 extra customers, all with the same amount of equipment and the same number of drivers, because we’re more efficient. So, it’s actually tough to keep track of the KPIs, but in a good way.

Q: What’s the biggest issue in food distribution that you see looming in the near future?

A: For this industry, and for business in general, I believe that automation and technological advances will increase at a pace faster than we’ve seen historically. It’s a positive trend that will lead to better transportation, warehousing and distribution than we see today. The reality of self-driving trucks is only a matter of time, and there will be other technological advances we may not even be able to imagine right now. As for our company, we’ve already taken the first step in embracing automation by implementing automated route planning.

Q: If you could give one piece of advice to a food distribution transport planning team, what would it be?

A: It’s very simple. I would one hundred percent, absolutely and adamantly urge them to go with an automated approach to transportation planning and execution. And here’s the important thing – you need to put forth the initial work that’s necessary to get clean data that will allow that program to properly do what it’s intended to do. Making that little bit of effort up front will make everything so much more efficient. It will positively impact the bottom line and very much prove its worth in a short amount of time.

Tried the Product Tour and Ready to Get Into Gear?

Book your full demo with our team today to see how our advanced routing software can help you accelerate performance.