In diesem Beitrag vorgestellt

A View from the Top: Industrial Manufacturing Leaders Share Their Digital Transformation Priorities

A View from the Top: Industrial Manufacturing Leaders Share Their Digital Transformation Priorities

6 Juli 2023

Aptean Staff Writer

Aptean Staff Writer

Terms like "smart manufacturing" and "digital transformation" get used a lot but we need to distinguish discussion from action. While many industrial manufacturers would like to automate operations and drive growth, how advanced is digital transformation in manufacturing? And which technologies and manufacturing software solutions are leaders prioritizing to drive their digital transformation strategy?

To gain greater insight into manufacturing’s digitization, Aptean surveyed 150 C-Suite decision-makers within industrial manufacturing companies in North America in late 2022. And we’d like to share some of our key findings with you.

Our research revealed a sector with ambitious digital transformation (DX) goals, but senior leaders are being selective about the technologies that they invest in. Let’s dive deeper into the findings:

How Advanced Is Digital Transformation in Industrial Manufacturing?

One thing made clear by our research is the importance of automation to industrial manufacturing’s future. Digital transformation isn’t a long-term ambition; for most manufacturers, it’s a current imperative for saving costs and driving value in a challenging economic climate.

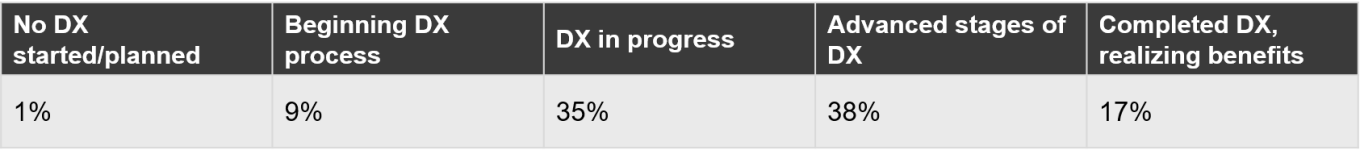

Most industrial manufacturing companies are already in the process of digital transformation—and nearly a fifth have completed DX projects and realized the benefits.

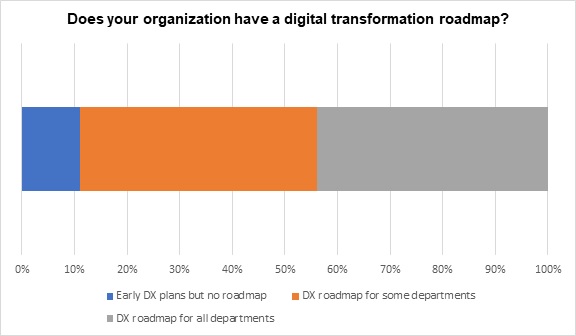

The projects that manufacturing leaders have embarked on are not isolated initiatives, either. 89% of C-Suite decision-makers say they have a cohesive digital transformation strategy in place for some or all departments.

What does this mean? Manufacturers holding back on digital transformation are falling further behind industry pacesetters. It is no longer a case of ‘if and when’ to automate systems and processes, but how quickly you can execute your digital transformation strategy.

To accelerate this transformation, industrial manufacturers can benchmark your current digital capabilities against other companies in the market and use this information to develop a roadmap.

What Manufacturing Problems Can Digital Transformation Solve?

Industrial manufacturers are operating in a highly pressurized market, and our research revealed these three core challenges that companies are most concerned about:

Rising material and operating costs (47% said this was a major challenge to their organization)

Labor and skills shortages (32%)

Finding new business/customers (31%)

Industry leaders are using digital transformation to address these issues—finding new opportunities to streamline resources while improving productivity.

For example, when it comes to mitigating rising business costs, one VP of Operations told us that digital transformation “accelerates our company’s operational efficiency in response to market competition.” Another C-Suite decision-maker said digital transformation is allowing their enterprise to conduct better data analysis so they can identify new cost saving opportunities.

Our research also revealed that process automation is helping industrial manufacturers to minimize the impact of skills and labor shortages. One CIO admitted that digital transformation “helps us to reduce the number of employees that we need,” while another IT Director remarked that “digital transformation has a valuable impact on our organization because we rely less on doing things manually.”

“Digital transformation has a valuable impact on our organization because we rely less on doing things manually.”

In addition to refining resources and processes, digital transformation is helping industrial manufacturers to accelerate innovation. A number of C-Suite decision-makers told Aptean that investing in new technologies is enabling them to develop better designs, work more dynamically and deepen partners’ trust in their capabilities. All while protecting their business information and helping their company to keep up with industry standards.

What does this mean? Industrial manufacturers must ensure that digital transformation strategies are centered around problem-solving, to ensure all software investments add value.

A well-prioritized strategy will help you to select and implement technologies in a way that drives progress towards your intended results. It will also be easier to secure company-wide buy-in if you start with the "big wins."

What Technologies Are Industrial Manufacturers Using to Deliver Digital Transformation?

While the need for digital transformation is widely recognized, rising business costs have made industrial manufacturers selective about the technologies they are investing in.

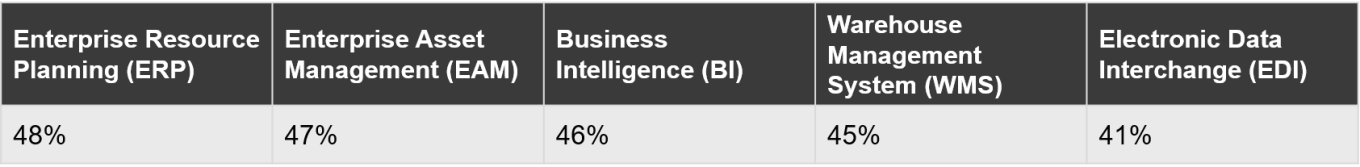

With efficiency high on manufacturers’ list of concerns, there has been significant investment in solutions that deliver broad benefits, such as industrial manufacturing ERP cloud-based software, which help to increase speed of production and remove data silos.

Our survey also revealed that many manufacturing companies are investing in EAM software to ensure equipment reliability, along with solutions that support insight and idea sharing, such as business intelligence (BI) tools and electronic data interchange (EDI) software.

In addition, we found that C-Suite decision-makers are leaning on the expertise of external technology vendors to execute their digital transformation strategy. Over 80% of manufacturing leaders have bought solutions rather than building a bespoke system, with just 16% opting to develop their own solutions in-house.

What does this mean? Industrial manufacturers need to consider both strength and depth when choosing which technologies should drive digital transformation projects. Industry leaders are getting strong ROI from solutions that deliver end-to-end value, such as ERP.

As you invest in new technologies, it’s also important to consider how these solutions will work alongside your existing infrastructure to drive holistic improvement. Otherwise, you risk running multiple siloed systems that demand a lot of time and energy, but which don’t deliver cohesive results.

Is Digital Transformation Driving Value for Industrial Manufacturers?

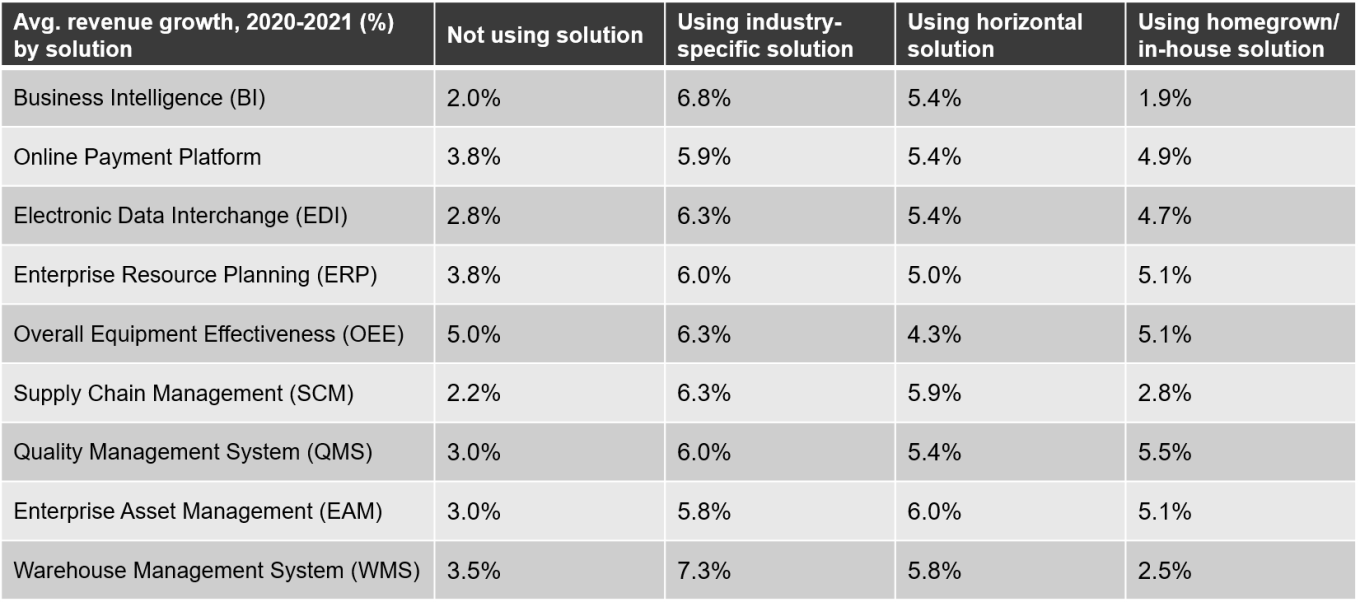

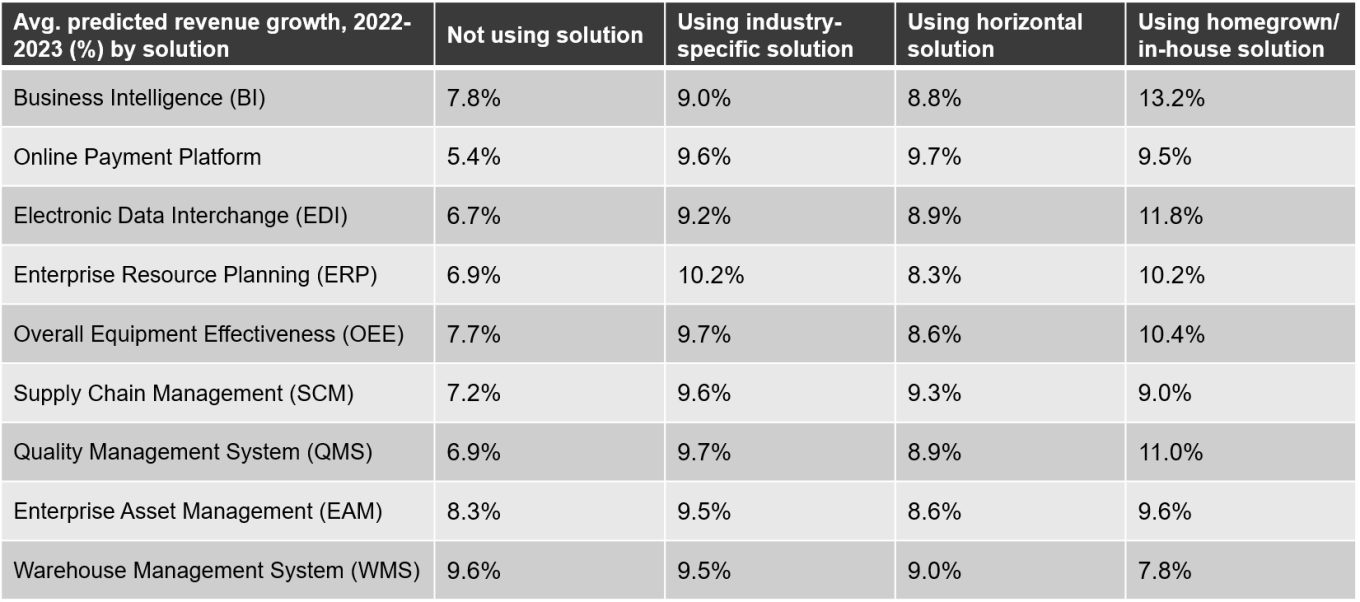

Interestingly, it’s not just choice of technology that is influencing the effectiveness of manufacturers’ digital transformation strategies. Our research found the type of solution manufacturing leaders choose can impact sales prospects.

For example, industrial manufacturers using industry-specific solutions are almost always more likely to experience higher year-on-year revenue growth than those using horizontal or homegrown technology.

When we conducted this research survey in Q4 last year, industrial manufacturers using industry-specific technology predicted that their revenue growth would be higher in 2023 than 2022. For example, companies using a manufacturing ERP system forecast a 10.2% year-on-year revenue increase in 2023, compared to 8.3% among companies using a horizontal and just 6.9% among companies not using any digital solution.

Of course, factors such as macro-economic pressures will determine whether these predictions hold true. However, Aptean will be re-surveying industrial manufacturing leaders in Q4 this year for an update on their 2023 performance.

What does this mean? Sector-specific software has been proven to increase revenue growth for industrial manufacturers embarking on digital transformation. As a result, organizations with operational software already in place may want to upgrade from generic systems to solutions with manufacturing-specific capabilities.

Increased revenue is just one of the advantages of digital transformation in manufacturing. Our research revealed multiple benefits, with C-Suite decision-makers citing:

Wider access to information

Faster business analysis and meaningful business insights

Improved customer experience

Less reliance on third-party suppliers

Streamlined processes

Greater reliability

Employees free to spend time on higher value tasks

No more human errors

Better corporate image

Smart manufacturing technologies are empowering companies to become more data-driven, meet customer needs and build a reputation as a reliable and efficient manufacturer. One senior leader summed it up when they told Aptean that digital transformation “has given me a ton of confidence.”

What’s Next for Digital Transformation in Manufacturing?

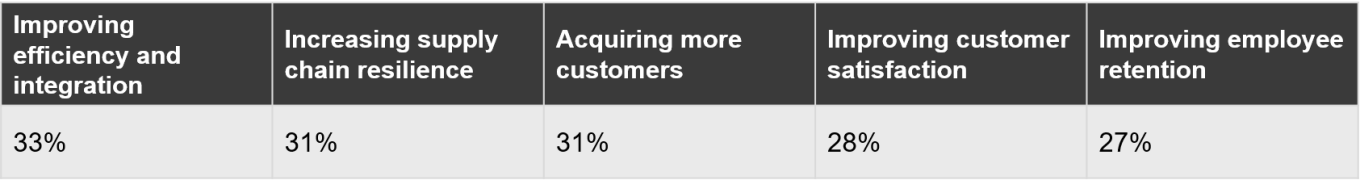

To understand how digital transformation priorities will evolve in 2023, Aptean asked industrial manufacturing leaders to list their top five priorities over the next twelve months.

Digital transformation strategies will play a key role in helping organizations to realize these changes by automating more processes, enhancing data insights and speeding up both production and product innovation. However, it’s important that manufacturing leaders work with software vendors that understand their sector and can act as a trusted partner throughout the digital transformation journey to ensure new solutions drive ROI.

The right-fit digital transformation partner will recommend many of the core solutions we’ve discussed, including industrial manufacturing ERP software and BI tools, while also discussing further opportunities to add value. For example, EDI software can facilitate faster data exchange and improve collaboration with trading partners, while payment software can automate the accounts receivable process to get paid faster.

This holistic ecosystem approach to digitization is a practice adopted by Aptean. We work closely with manufacturing decision-makers to help you realize your strategic digital transformation goals using industry-specific technology.

Our manufacturing software suite—which includes aforementioned specialist ERP, EAM and EDI software and also Routing & Scheduling and Ship tools—is designed to help industrial manufacturers streamline processes, enhance production and grow your business.

“Aptean Industrial Manufacturing ERP has enabled our growth as a business. We’ve been able to scale up quickly and easily, with revenue increasing four-fold since implementing the system.”

But more importantly, we’ll encourage your business to situate new technology investment within a cohesive digital transformation strategy that includes:

A transformation roadmap for all departments (not just one area of your business)

Clear assignment of roles and responsibilities to senior team members

Budget and resource allocated to the maintenance of new digital systems and processes

Regular review meetings to assess your progress and update your DX strategy as company priorities evolve

We’ve already helped organizations like Anderson Dahlen, Portable Pipe Hangers and The Metalworking Group to transform their operations and get Ready For What’s Next, Now®.

For more industry trends and insights, download Aptean’s 2023 manufacturing forecast.

Or, request a demo to see how our industrial manufacturing solutions can strengthen your digital transformation strategy.

Beginnen Sie noch heute mit der Transformation Ihres Unternehmens

Sie möchten Ihr industrielles Fertigungsunternehmen weiterentwickeln? Wir helfen Ihnen gerne dabei.